Asked to name one of the most challenging horizontal directional-drilling jobs ever tackled by REM Directional, owner Joel Colgrove Jr. doesn’t hesitate for long: A 7,000-foot bore for a 42-inch-diameter natural gas pipeline, drilled 80 feet under the bottom of a roughly...

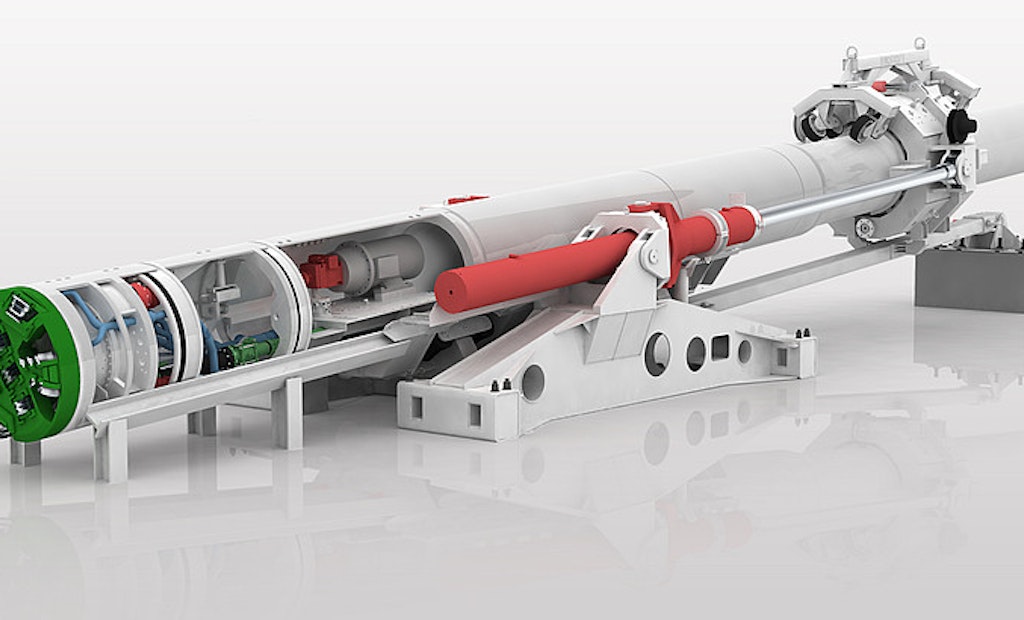

Pipe-Thrusters Bring the Force to Finish the Job

Contractor uses two machines to help push and pull pipe for a 7,000-foot bore job

Popular Stories

Discussion

Comments on this site are submitted by users and are not endorsed by nor do they reflect the views or opinions of COLE Publishing, Inc. Comments are moderated before being posted.