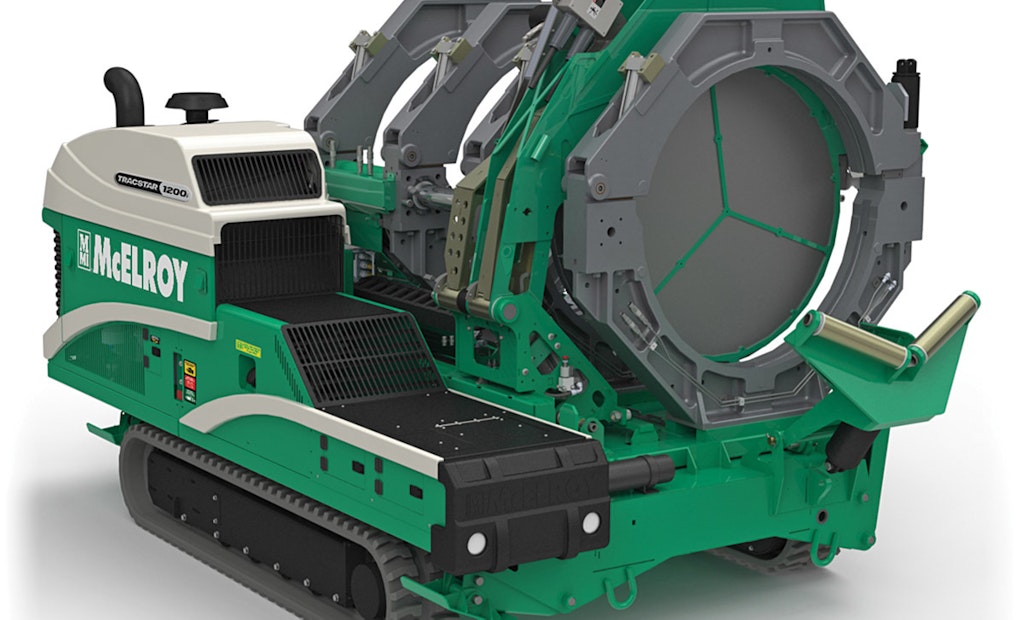

Tracked fusion machines are often the choice for job sites fusing long pipelines. Self-propelled via rubber crawler tracks, these vehicles are designed to traverse rough terrain and steep grades, offering ease of maneuverability and freedom of movement.

McElroy recently released...