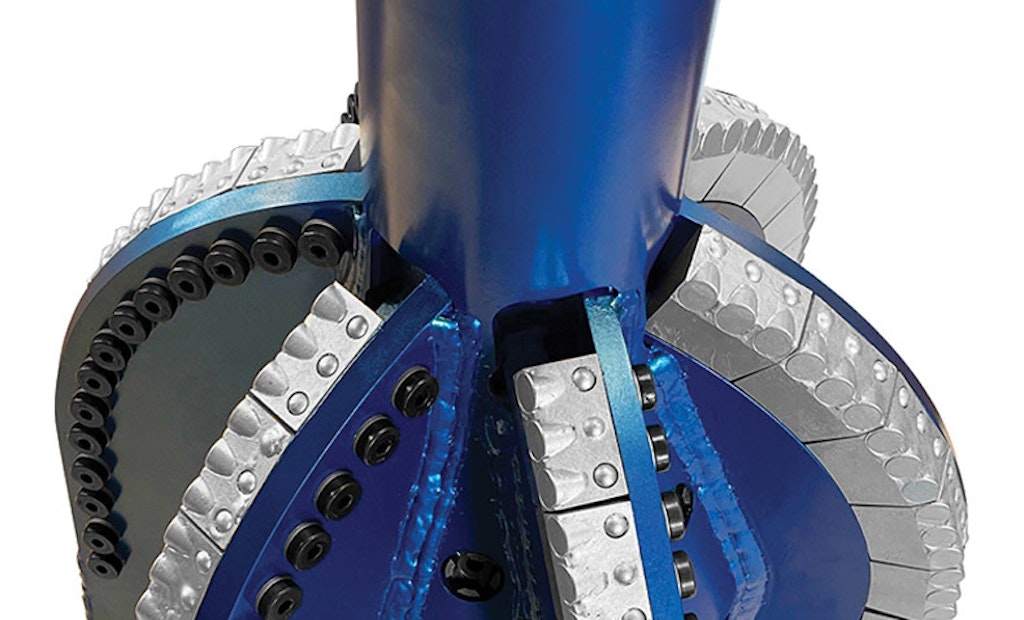

Horizontal directional drilling crews are charged with being able to bore through just about any ground condition. However, when they encounter rock, the job is a bit more difficult. That makes picking the proper tool critical for a successful project. The Shark PDC...

Product Spotlight - January 2022

Popular Stories

Discussion

Comments on this site are submitted by users and are not endorsed by nor do they reflect the views or opinions of COLE Publishing, Inc. Comments are moderated before being posted.