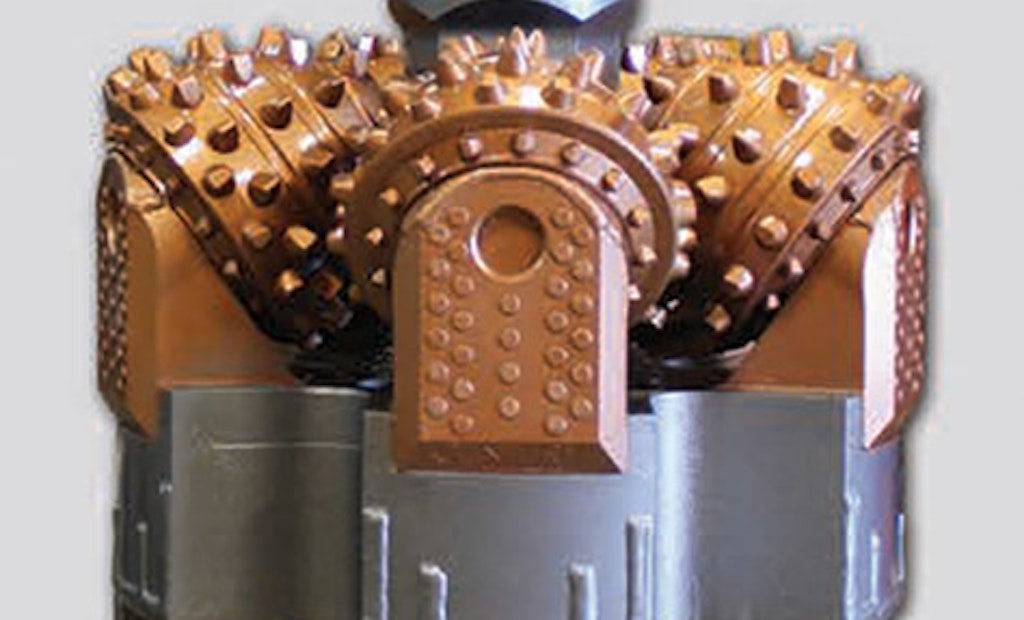

A hole opener is a cost-effective way to enlarge a pre-drilled pilot hole or to ensure that the gauge is maintained in a deviated hole. The aggressive tools are made to be worked. Hard. With that comes inevitable maintenance and repair concerns. Falcon FR Series Hole...

Product Spotlight - April 2022

Popular Stories

Discussion

Comments on this site are submitted by users and are not endorsed by nor do they reflect the views or opinions of COLE Publishing, Inc. Comments are moderated before being posted.