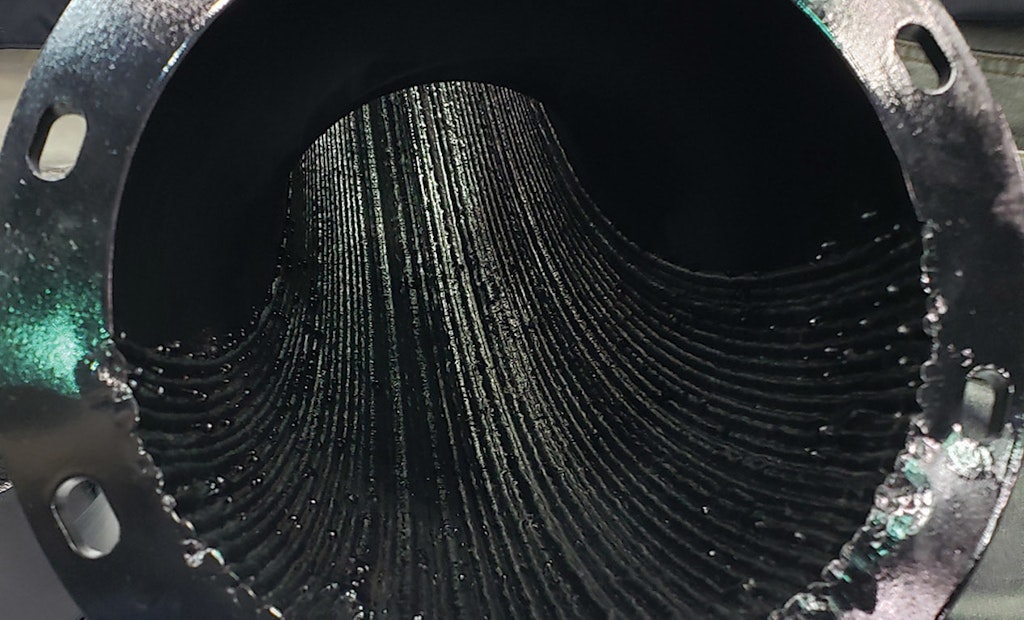

Just like how a pitcher’s elbow takes a lot of stress, the boom elbow on a hydrovac unit typically is one of the machine’s most stressed components. Sometimes elbows even need to be changed out several times a year on highly used units. So when Glenn Gevik, president of EMCO,...

Product Spotlight - July 2020

Popular Stories

Discussion

Comments on this site are submitted by users and are not endorsed by nor do they reflect the views or opinions of COLE Publishing, Inc. Comments are moderated before being posted.